Cooler Adapter: Difference between revisions

Create page, installation instructions |

Build instructions |

||

| Line 1: | Line 1: | ||

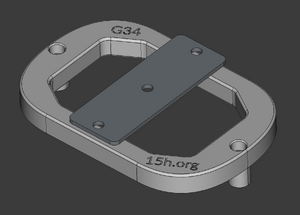

The 15h.org Cooler Adapter is an adapter designed to allow an inexpensive modern CPU cooler (the Thermalright Assassin King 120 SE) to be installed on a [[Socket G34]] motherboard. This cooler can be purchased new for approximately $20 USD from multiple retailers, and is rated to cool a TDP of up to 235W. Its large, wide base is capable of covering both dies of a G34 CPU, and its heat pipe arrangement makes it well-suited for use on dense dual- and quad-socket motherboards. | [[File:CoolerAdapter.png|thumb|Both main parts of the Cooler Adapter]] | ||

The 15h.org Cooler Adapter is an adapter designed to allow an inexpensive modern CPU cooler (the [https://www.thermalright.com/product/assassin-king-120-se/ Thermalright Assassin King 120 SE]) to be installed on a [[Socket G34]] motherboard. This cooler can be purchased new for approximately $20 USD from multiple retailers, and is rated to cool a TDP of up to 235W. Its large, wide base is capable of covering both dies of a G34 CPU, and its heat pipe arrangement makes it well-suited for use on dense dual- and quad-socket motherboards. | |||

The Cooler Adapter is currently under development. If you would like to test a "beta" kit on your board and report results, ask in [[Matrix|the 15h.org Matrix room]]. | The Cooler Adapter is currently under development. If you would like to test a "beta" kit on your board and report results, ask in [[Matrix|the 15h.org Matrix room]]. | ||

| Line 36: | Line 38: | ||

# Ensure the cooler is firmly attached to the board. | # Ensure the cooler is firmly attached to the board. | ||

# Reattach the fan to the cooler, and plug it into the appropriate CPU fan header on the board. | # Reattach the fan to the cooler, and plug it into the appropriate CPU fan header on the board. | ||

== Making the Adapter == | |||

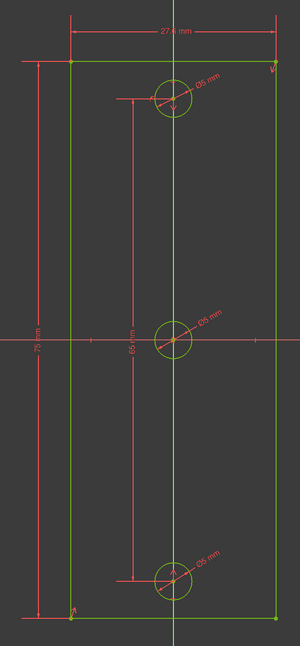

[[File:MountingBarSketch.png|thumb|Drawing of a simple mounting bar]] | |||

You will need: | |||

* A high-temperature 3D-printer filament (see below), and a 3D printer able to print it | |||

* Two M3x18 metric screws (SHCS, BHCS, pan head, etc should all work - to attach the cooler to the bracket) | |||

* Two M3x4x5mm heat-set threaded inserts | |||

* Two 5/8" #6-32 imperial socket-head cap screws (to attach the bracket to the socket's backplate) | |||

* Aluminium (or other metal) bar stock, 2.0mm thick, and at least 27.6mm wide and 75mm long. | |||

* Some way to cut that bar stock to size (mill if you've got one, a hacksaw/Dremel and files would work too) | |||

* Drill, 5mm or 13/64" | |||

The adapter consists of two parts - the mounting bracket, and the mounting bar. The bracket can be 3D-printed in a high-temperature, low-heat-creep material (such as fibre-reinforced ABS or ASA, PA6, PC, PEEK, PEKK, PPS, or PSU). Be aware that, while theoretically suitable, PA6 and other nylons are more susceptible to heat creep during prolonged service at high temperatures than other filaments here. The bracket CANNOT safely be printed in common lower-temperature materials such as PLA or PETG. Look for a 1.8 Mpa Heat Deflection Temperature of above 100 degrees Celsius - if your filament's datasheet does not mention a heat deflection temperature, it is likely too low. If using a carbon-fibre-reinforced (as opposed to glass-fibre-reinforced or non-fibre-reinforced) material, ensure that the conductive carbon-fibre particles embedded in the material do not cause short-circuits on the motherboard (at a minimum, ensure the surface of the part printed relatively smoothly and carefully remove any strings). | |||

The mounting bar, which is relatively thin and directly contacts the CPU cooler, cannot be 3D-printed in plastic. Aluminum works, and is easy to work with. A simple mounting bar can be cut from 2.0 mm thick bar stock, machined to 27.6mm in width, and drilled according to the drawing in this section. Alternatively, a completed mounting bar could be ordered from a service such as SendCutSend using the attached STEP file. | |||

Once you have your mounting bracket, install two standard M3x4x5 heat-set threaded inserts into its bottom (non-text) side. Install two M3x18mm screws (any reasonably common screw head should be okay - just make sure the head won't hit anything on the motherboard) into the inserts, with the threads of the screws sticking up through the bracket and out of the text side (so that the CPU cooler can mount to them). | |||

For both types of screw in the bracket, stainless steel is recommended in order to minimize heat transfer into the plastic part. | |||

The FreeCAD source file, as well as AMF files and a STEP file for the mounting bar, can be downloaded from [https://git.15h.org/Dodoid/CoolerAdapter the Git repository]. | |||

Revision as of 10:03, 19 October 2025

The 15h.org Cooler Adapter is an adapter designed to allow an inexpensive modern CPU cooler (the Thermalright Assassin King 120 SE) to be installed on a Socket G34 motherboard. This cooler can be purchased new for approximately $20 USD from multiple retailers, and is rated to cool a TDP of up to 235W. Its large, wide base is capable of covering both dies of a G34 CPU, and its heat pipe arrangement makes it well-suited for use on dense dual- and quad-socket motherboards.

The Cooler Adapter is currently under development. If you would like to test a "beta" kit on your board and report results, ask in the 15h.org Matrix room.

Installation

Cooler Requirement

In addition to your Cooler Adapter kit, purchase a Thermalright Assassin King 120 SE. ARGB on the included fan is optional and is probably not supported natively on any G34 board, but they are commonly only available with ARGB.

Cooler Modifications

As delivered, the Thermalright Assassin King 120 SE has a mounting bar held onto its block by a large, flat thumb screw at the center of the bar (underneath the fin stack), and it has two spring-loaded Philips-headed nuts, retained in the mounting bar by one snap ring each. The snap rings are on the bottom of the mounting bar, around the shaft of each nut.

- For better access, unclip the fan from the cooler.

- Cut both snap rings off using wirecutters or sidecutters, allowing the nuts (and their springs) to lift out of the stock mounting bar. Discard snap rings.

- Use a pair of pliers or small vise-grips to loosen the large central thumb screw - it can be quite tight.

- Remove the thumb screw with your fingers.

- If you wish to use the cooler with its stock mounting hardware (on a non-G34 socket) again in the future, simply reinstall the stock mounting bar and continue to use the Philips-headed nuts and their springs. The snap rings are not necessary when the cooler is installed, and serve only to prevent the nuts falling out of the bar when the cooler is not mounted.

Mounting Bar Assembly

- Place the new aluminum mounting bar (included with the cooler adapter kit) in the slot in the cooler's block where the stock mounting bar sat. If your new mounting bar has a thinner (cutout) section in its center, point the cutout upwards, towards the fin stack.

- Using the large thumb screw that came with the cooler, screw down the new mounting bar through its middle hole.

- Tighten the thumb screw using pliers or small vise-grips.

Assembly on the Socket

- Install your CPU in its socket according to your motherboard's manual.

- Place the adapter kit's mounting bracket on the motherboard, with the text on it facing upwards, and with its two "feet" resting over the two mounting nuts built into your G34 socket's backplate.

- Ensure the threads of the two M3 screws preinstalled in your bracket are pointing straight upwards (the cooler will attach to these).

- Ensure the bottoms of the "feet" are sitting flat on the board, and that no components (VRMs, parts of the socket, etc) are contacting the bracket.

- Using a hex key or a Torx screwdriver, tighten the two included 6-32 socket-head screws, attaching the bracket to the motherboard. Ensure the bracket is attached firmly.

- Apply thermal paste to your CPU.

- Lower your modified cooler, with its new mounting bar installed, over the bracket. Let the two threads that point upwards from the bracket pass through the two remaining holes on the new mounting bar.

- Gently thread the two Philips-headed nuts down onto the threads in the bracket, through their springs, and then through the holes in the mounting bar.

- Using a Philips screwdriver, tighten the nuts. Do not overtorque and risk damage to the board or bracket - a properly-installed cooler should have a 2-3mm gap between the top surface of the bracket and the bottom surface of the mounting bar. Stop when the screw feels firm and the springs have compressed in length by approximately 1.5mm.

- Ensure the cooler is firmly attached to the board.

- Reattach the fan to the cooler, and plug it into the appropriate CPU fan header on the board.

Making the Adapter

You will need:

- A high-temperature 3D-printer filament (see below), and a 3D printer able to print it

- Two M3x18 metric screws (SHCS, BHCS, pan head, etc should all work - to attach the cooler to the bracket)

- Two M3x4x5mm heat-set threaded inserts

- Two 5/8" #6-32 imperial socket-head cap screws (to attach the bracket to the socket's backplate)

- Aluminium (or other metal) bar stock, 2.0mm thick, and at least 27.6mm wide and 75mm long.

- Some way to cut that bar stock to size (mill if you've got one, a hacksaw/Dremel and files would work too)

- Drill, 5mm or 13/64"

The adapter consists of two parts - the mounting bracket, and the mounting bar. The bracket can be 3D-printed in a high-temperature, low-heat-creep material (such as fibre-reinforced ABS or ASA, PA6, PC, PEEK, PEKK, PPS, or PSU). Be aware that, while theoretically suitable, PA6 and other nylons are more susceptible to heat creep during prolonged service at high temperatures than other filaments here. The bracket CANNOT safely be printed in common lower-temperature materials such as PLA or PETG. Look for a 1.8 Mpa Heat Deflection Temperature of above 100 degrees Celsius - if your filament's datasheet does not mention a heat deflection temperature, it is likely too low. If using a carbon-fibre-reinforced (as opposed to glass-fibre-reinforced or non-fibre-reinforced) material, ensure that the conductive carbon-fibre particles embedded in the material do not cause short-circuits on the motherboard (at a minimum, ensure the surface of the part printed relatively smoothly and carefully remove any strings).

The mounting bar, which is relatively thin and directly contacts the CPU cooler, cannot be 3D-printed in plastic. Aluminum works, and is easy to work with. A simple mounting bar can be cut from 2.0 mm thick bar stock, machined to 27.6mm in width, and drilled according to the drawing in this section. Alternatively, a completed mounting bar could be ordered from a service such as SendCutSend using the attached STEP file.

Once you have your mounting bracket, install two standard M3x4x5 heat-set threaded inserts into its bottom (non-text) side. Install two M3x18mm screws (any reasonably common screw head should be okay - just make sure the head won't hit anything on the motherboard) into the inserts, with the threads of the screws sticking up through the bracket and out of the text side (so that the CPU cooler can mount to them).

For both types of screw in the bracket, stainless steel is recommended in order to minimize heat transfer into the plastic part.

The FreeCAD source file, as well as AMF files and a STEP file for the mounting bar, can be downloaded from the Git repository.